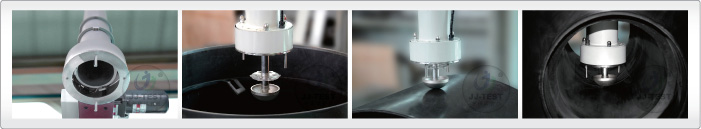

1.Vacuum system is introduced to lift the weight, with big suction and high efficiency.

2.With the functions of measuring instantaneous impact velocity, automatic catching impact weight and anti-rebounded.

3.System frame with the adjustable cantilever structure and open test space, makes it easier for sample installation.

4.Actions before impact : the weight is lifted into the protection tube by suction, then the protection tube is fixed automatically at a position of the sowchannel center, click “impact” button to release the impact weight. Actions after impact: the weight is caught automatically and lifted into the protection tube again.

5.Protection tube is installed vertically and with the internal wall roughness less than 0.8. The friction is very low which ensure the real impact velocity no less than 95% of theoretical value.

6.Protection tube location checking system is installed at the bottom of protection tube, which ensures the tube stop at the position of 50mm above the impact point on sample; Also, the position can be controlled at any point on customer’s requirement.

7.Dual redundancy design of the limit sensor ensures control more safety.